JINGYE STEEL GROUP CO., LTD

How are steel coils produced

Apr 03,2025

The production of steel coils is a complex and multi-step process that involves multiple processing steps from raw materials to finished products. The following are the main processes for steel coil production:

1. Raw material preparation and steel making

The production of steel coils begins in steelmaking, and the first thing to do is to prepare raw materials such as iron ore, coke and limestone. These raw materials are smelted by blast furnaces to produce iron, and then steel is made through a converter or electric furnace. During the steelmaking process, different types of steels are produced by adding alloy elements and precisely controlling the temperature and chemical composition.

2. Continuous casting

After the steelmaking is completed, the molten steel is injected into the continuous casting machine. The continuous casting machine injects the liquid steel into the crystallizer, and through cooling and solidification, the liquid steel solidifies it into a long casting billet. The key to this step is to control the cooling speed to ensure the mass and size of the casting billet.

3. Hot rolling

After continuous casting, the casting billet enters the hot rolling workshop. Hot rolling is the formation of the desired steel coil by multi-rolling after heating the billet to an appropriate temperature (typically 1150-1280°C). During the hot rolling process, the steel billet passes through roll systems such as rough rolling mill, finishing mill and fine rolling mill to gradually reduce the cross-sectional size of the billet, and finally form a steel coil.

4. Pickling and annealing

The hot-rolled steel coil usually has some oxides and rust substances attached to the surface. To improve the surface quality of the steel coil, a pickling treatment is usually performed, which is soaked in an acidic solution to remove oxides and impurities from the surface. After that, the coil may be annealed to remove internal stress and improve the toughness and processability of the material.

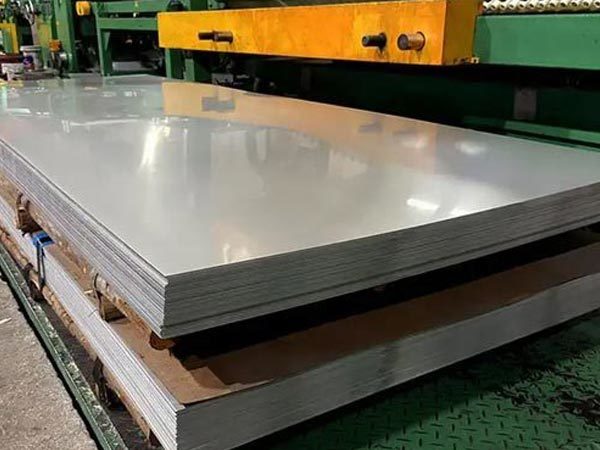

5. Cold rolling

The steel coils that have been pickled and annealed enter the cold rolling process. Cold rolling is the rolling of the steel coil through a cold rolling mill at room temperature to further reduce its thickness while improving the surface finish and dimensional accuracy.

6. Coating and coating

In order to improve the corrosion resistance of the steel coil, the cold-rolled steel coil may be subjected to aluminum zinc or galvanized treatment. In addition, coating treatment can also be performed by spraying, coating or roller coating to increase the weather resistance and appearance of the steel coil.

7. Cutting and packaging

Finally, the coated steel coils are cut to the required size and are strictly inspected to ensure that the quality meets the standards. Qualified steel coils will be packaged, marked accordingly and ready for shipment.

Summarize

The production process of steel coils covers multiple steps from raw material preparation, steelmaking, continuous casting, hot rolling, pickling, annealing, cold rolling, plating, coating to cutting and packaging. Each step plays a crucial role in the quality and performance of the final product. Different types of steel coils (such as hot and cold rolled coils) may vary in production processes, but the overall framework is roughly the same.

Hot Tags:

PREVIOUS:

NEXT: